YANZHAO

Precision Screening Solutions Since 1998

Global manufacturer of custom wedge wires, offering high-performance, anti-clogging products to improve your productivity and extend your equipment lifespan.

Global manufacturer of custom wedge wires, offering high-performance, anti-clogging products to improve your productivity and extend your equipment lifespan.

Wedge wire products consist of a V-shaped profile wire and support rod. The profile wire is fully welded to the support rod using an advanced resistance welding process with a precisely set gap (gap width). This structure has extremely high mechanical strength and ensures the accuracy of filtration or sieving.

The unique V-shaped cut creates a slit that gradually widens from the inside out. This ensures that particles have only two contact points as they pass through, minimizing clogging and maintaining extremely high fluid throughput efficiency.

Carefully selected raw materials and wire winding: We use 304/316L stainless steel or other alloys and process the raw materials into V-shaped wires using high-precision equipment to ensure absolute accuracy of the cross-sectional geometry.

Automated Welding and Gap Control: Utilizing fully automated, high-frequency resistance welding technology, each junction of the winding wire and support bar is securely welded, ensuring a robust product structure. Simultaneously, a PLC precision control system rigorously ensures the consistency of the width of each gap.

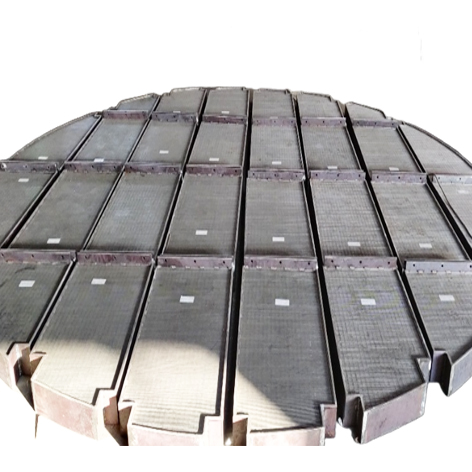

Customized molding and surface treatment: Products can be manufactured into complex shapes such as flat plates, cylinders, baskets, and arcs according to customer needs. After completion, surface treatments such as pickling and passivation or electropolishing are performed to improve corrosion resistance or meet sanitary requirements.

V-shaped profiles for maximum non-clogging flow and separation efficiency. Ideal for dewatering and filtration systems.

High-strength, durable wedge wire baskets built for demanding centrifuge applications. Guaranteed structural integrity.

Oil well sand control screens consist of a base pipe, multiple layers of sand control filter sleeves, and an outer protective sleeve, from the inside out.

Precision support grids, catalyst baskets, and distributors engineered for high-pressure and critical chemical processing environments.

Leveraging our heritage in the “Hometown of Wire Mesh,” we combine decades of manufacturing expertise with strict QA/QC standards to deliver reliable, long-term screening solutions.